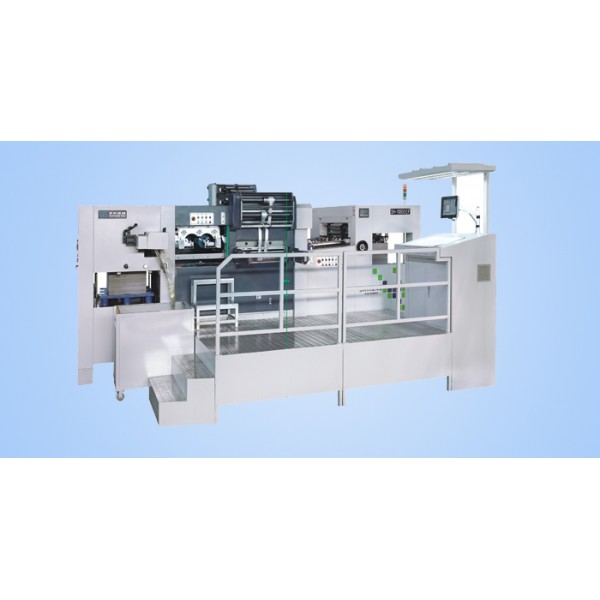

This machine can be applied to paper products, printing and packaging company's products cold, hot die-cutting, embossing, embossed; bronzing process, particularly the unique delivery foil anodized three vertical and two horizontal axis control system, printing layout according to the customer Select vertical, horizontal, or two-way simultaneous precise control anodized walk, jump, to conserve the use of foil material to reduce material costs.

Maximum paper size: 1050 × 740mm

Minimum sheet size: 400 × 360mm

Die-cutting range: 1040 × 730mm Maximum stamping Range: 1020 × 730mm

Acceptable Paper range: 80-1200 g

Maximum operating pressure: 300 tons

Minimum blade size: 8mm

The maximum roll diameter discharge foil: 200mm

Electric hot plate heating: Area 12

Heating plate temperature range: 0 ~ 200 ℃

Anodized aluminum foil transport axes: longitudinal 3-axis, 2-axis transverse

Machine Power (kW): 50 KW Weight: 17 tons

Power requirements: 380∨ three-phase 50

Machine Dimensions (m): 7.1 × 4.2 × 2.4m (L × W × H)

Maximum printing speed: 6000 / hour (typesetting, die-cut paper and operational factors depending on product availability)

Maximum cutting speed 7500 rev / hour (depending on layout, paper and operational factors may be die-cut products)

Machinery Co., Ltd., Shenzhen Shi Heng Sheng Ding Group companies to produce high-performance automatic platen die-cutting machine, platen die cutting waste discharge machines and automatic stamping machine (with holographic security locate hot) -based, and passed ISO9001: 2000 quality system certification European safety performance test and get CE certification, the company follows the 'technical innovation, quality and excellence' business philosophy, sincerely provide customers the best quality service, sound management system and modern hardware and software environment Our product quality is the most effective protection. The high-quality professional R & D team, a sound service system, at home and abroad with multiple offices and a number of service agents, is committed to the entire process of India Services, provides a complete solution

for India after the goal for the printing and packaging of users, the Group subsidiaries fine division, responsible for the development and manufacture of different projects. To 'revitalize national industry, the achievements of the international brands' as the goal, uphold 'unity, action, service, innovation' entrepreneurial spirit, commitment to 'allow customers to get the best interests' to standardization, serialization, internationalization of products to meet customer demand, internal covering more than 20 provinces, sold outside South America, North America, Southeast Asia, Central and Eastern Europe and so on, with dozens of advanced automated processing equipment, products, technology has reached the international advanced level.

Wap Version

Wap Version