The machine is consist of automatic paper feeder ,printer slotter and ,can finish the 3ply / 5ply paper printing and slotting procedures in once time.

Complete machine configuration: Pneumatic printing plate lifting, pneumatic units locking, electrical phase adjustment, light pressure type auto feeder (self-made) can improve the board anti-pressure ability, reduce the flute damage.

| Parameter | |||

|

Machine design speed |

240pcs/min. | Min. carton height | 50mm |

| Economic speed | 220pcs/min. | Max. carton height | 350mm |

| Max. feeding size | 700*1800mm | Single knife length | 170mm |

| Min. feeding size | 170x450mm |

Upper slotter knife size |

60 degree with angle x L 115mm |

| Skip feeding size | 115x02000mm | ||

| Max. printing size | 700x1700mm | 30 degree without angle x L 58mm | |

| Wallboard thickness | 30mm | ||

| Wallboard inner width | 2000mm | Positive slotter knives direction | L 80 x W80 x H50mm |

| Printing roller size | 228x1800mm | Negative slotter knives direction | L160 x W60 x H50mm |

| Slotting and diecutting precision | ≤±1.5 | Overprinting precision | ≤±0.75 |

Lead edge feeder unit:

1)Automatic light pressure paper feeding has the proprietary technology,no damage to corrugated line,easy to paper feeding,more precise.(can also choose free pressure as customers requirement.)

2) Can process hard thinner sheet include 3ply E flute board

3)Auto feeder with suction device ,can adjust the blast capacity as per different paper curve condition ,ensure smooth feeder paper.

Printing part:

1)Printing roller

2)High quality steel plate material, surface grinding and hardness .

3)Optional: (Full format plate groove, gear fixed test paper plate , for 9mm hanging plate,)

4)Fast loading and unloading printing plate, foot switch electric control positive and negative.)

5)Anilox roller and printing roller manual adjustment of gaps dial,adjustment range is 1-8mm

Slotting unit

(1)Creasing wheels choose Explosion-proof

1)Creasing wheels and the slotting knife holders is adjusted in transverse in synchronization.,6 shaft transverse moving,cutter(5 cutter electrically adjustment),creasing wheel(4 shafts transverse moving),shift fork(copper grinding),Horizontal nut(copper),(PLC touch screen adjustment,importing carton size,auto adjustment).

(2)Slotting knife adjustment

1)Slotting knives width is 5mm,can also choose 7mm

2)Alloy steel with heat treated of the knife tooth,guarantee the hardness and toughness.

3) Alloy steel with heat treated of the double blade knife tooth,sharp edge high precision.

4)Creasing wheels and the slotting knife holders is adjusted in transverse in manual,4 shaft transverse moving,carton height electrically adjustment.

5)Slotting knife manual adjustment of gaps dial ,adjustment range is 1-6mm,adjusted by gear crosshead shoe,when adjustment,drive gear always maintain correct bite status

(3)Slotting phase adjustment mechanism

1).Planet is a gear mechanism

2)Slotting phase is adjusted by electric digital input type 360, and the machine can be adjusted byrunning or stopping.

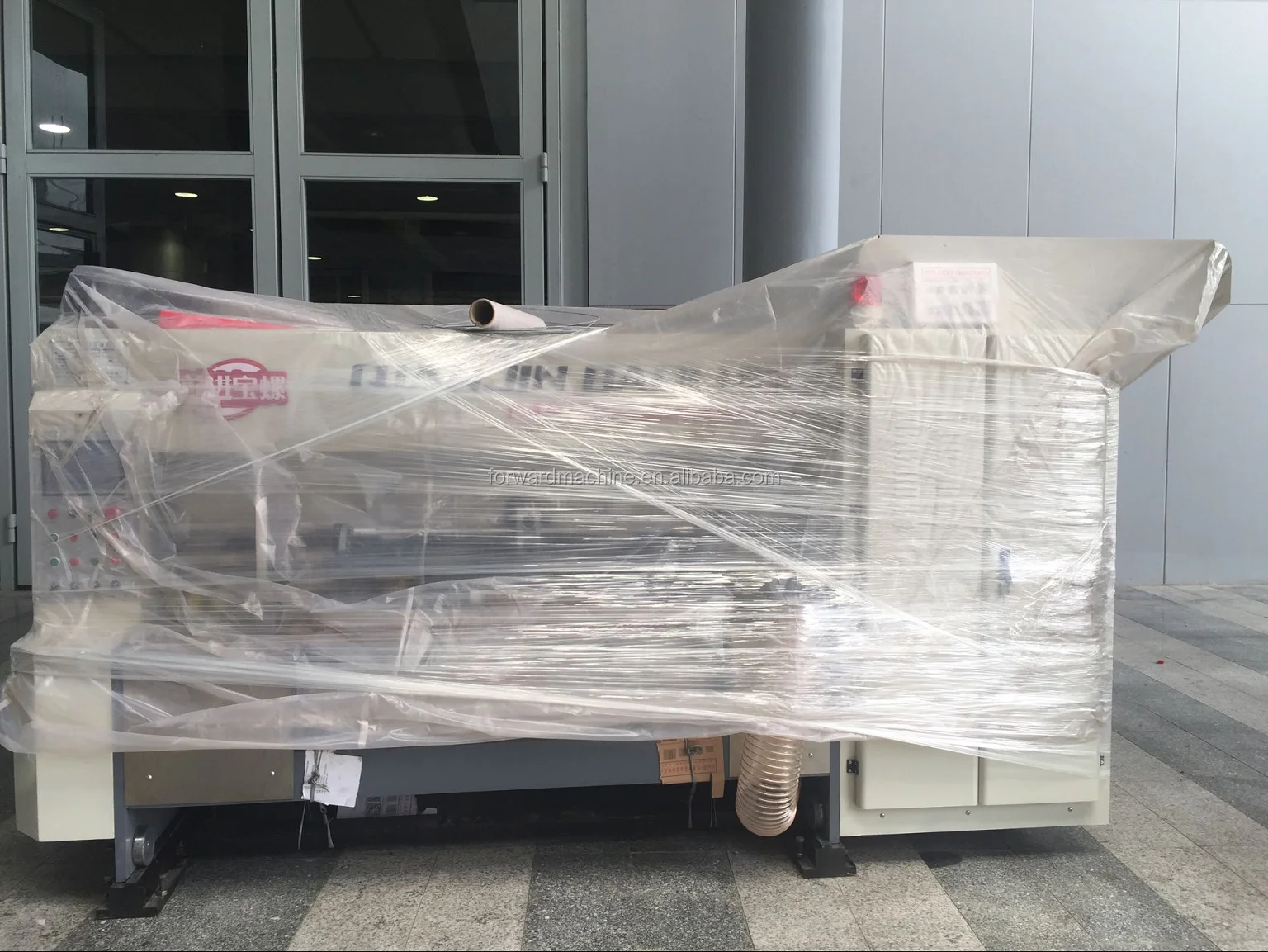

Q1. What is your terms of packing?

A: Plastic film or according to customer’s requirement.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Why Choose Us

1.High quality product----Our tenet is “quality first”.Good material,precise manufacturing processes and strict quality control can create excellent quality.

2.Competitive price----We have our own factory,scientific producing, direct-selling.So we can save the cost and supply low price.

3.Professional----- Our professional engineer can answer technical questions,help you solve technical problems and help you choose the most suitable product according to your requirment.

4.Delivery fast -----We are near port,and we have professional forwarder. Goods can be sent out within 30 to 60 working days based on order quantity.

5.Best service-----Answering e-mails or solving questions timely.

Delivery and update information on time.

Dongguang Qianjin Baoluo Carton Machinery Manufacture Factory was established in 1984. It is located in the south of Beijing, north of Jinan, with convenient water and land transportation. It is a professional enterprise specializing in the production of carton machinery and printing machinery. It has complete equipment, high degree of specialization, rich manufacturing experience, strong technical strength, advanced testing methods and complete management system.

Our factory has many mechanical models and complete specifications, which can meet the needs of different customers. In the spirit of excellence and excellence, our factory actively promotes comprehensive quality management. The products are beautiful and elegant, the process is rigorous and meticulous, and the price is reasonable. Perfect after-sales service has been well received by users all over the world for many years.

Our products ever sold to , South Africa ,Thailand, Malaysia ,Chile, India, Philippines ,Vietnam and so on.