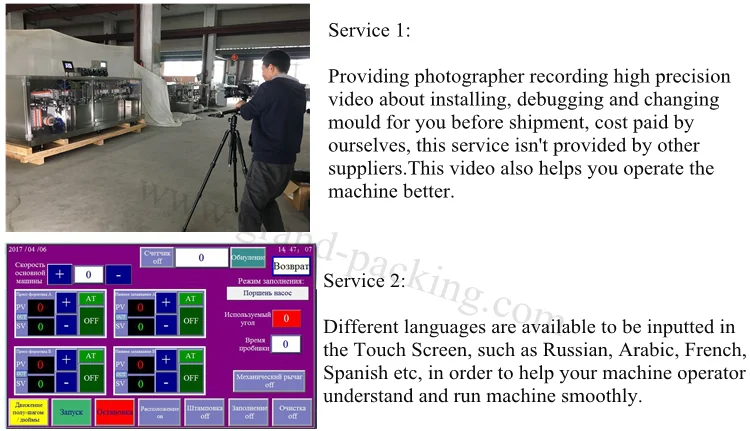

Main Features

1. The machine acquires such advantages as small volume, low energy consumption, convenient operation and cleaning.

2. Equipment standardization and component interchangeability enable molds to be changed quickly and accurately.

3. The design of bottom installation of the cam can increase the pressure atomizing oil pump, keep the cam groove lubricated, reduce wear and extend the service life of parts.

4. High-accuracy indexer is applied for slight vibration and operation noise lower than 80db. In addition, vacuum locating structure is used to achieve over 99.9% of the capsule probability.

5. The lower plane of dosing tray is the benchmark for three-dimensional adjustment, uniform gap, narrow filling quantity distribution and convenient cleaning.

6. HMI is applied for perfect functions. Besides, when material or capsules are lack or material channel is faulty, the machine can alarm and stop automatically. it can also count for every capsules and display the value of cumulative output.

Introduction of NJP-400 full automatic capsule filling machine

This model is an intermittent motion and hole plate type filling full automatic capsule filling equipment. It adopts optimization design for meeting the characteristics of Chinese medicine and the requirement of GMP, it has the characteristics of compact mechanism, small volume, lower noise, precision filling dosage, multi-function, stably running etc. It can finish the following motion at the same time: capsule feeding, capsule separating, powder filling, capsule rejecting, capsule locking, finished capsule discharge and die hole cleaning etc. It is the most ideal hard capsule filling equipment for the pharmaceutical and health food industry.

Overview

NJP-400 automatic capsule filling machine, as a newly designed product, can replace the semi-automatic capsule filling machine. The machine has attracted many clients, since it can be applicable in many areas, such as hospitals, pharmaceutical research institutes, laboratories, colleges and universities, small pharmaceutical factories and health care plants.

Main Technical Parameter

|

Equipment Model |

NJP-400C |

||

|

Machine weight |

800kg |

||

|

Overall dimension |

810 ×945× (1930+150) mm |

||

|

Motor power |

1.87kw + 2.2kw (Dust Collector) |

||

|

Power supply |

3 phase, AC 380V, 50Hz |

||

|

Max. Output |

24000capsules/h |

||

|

Capsule size |

00#~5# and safety capsule A~E |

||

|

Capsule using rate |

≥ 99.5% |

||

|

Noise index |

≤ 75dBA |

||

|

Dosage difference |

≤ ±3% (under more than 300mg dosing and 40~80 mesh after granulation) |

||

|

Water supply |

Water cycle pump compound water tank, or meet water source |

||

|

Vacuum degree |

-0.02~-0.06 MPa |

||

|

Water volume |

250L/hour |

||

|

Enter pipe inner-diameter |

20mm |

||

|

Waterspout inner-diameter |

27mm |

||

|

Working temperature |

21℃ ± 3℃ |

||

|

Working relative humidity |

40~55% |

||

|

Exhaust capacity |

210m3/h |

||

|

Special function |

Granule and powder mixed filing; Powder collector |

||

|

Control system |

Stepless frequency conversion control, PLC control, with touch screen |

||

|

Material |

Spare part contact with medicine adopt superior S.S 304 & GMP compliable material |

||

|

Criterion |

Comply to GMP completely |

||

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes

guarantee of the machine for 12 (twelve) months. During this Warranty

period, the seller will provide free spare parts that cause by the

machine’s quality within 10 days by fast courier upon receipt of buyer’s

notice.(we will also provide one set of spare parts /wear &tear

parts to customer along with the shippment of the machine.

Service 5: We

warmly welcome the suggestions from customer to make us grow better and

produce better machine along with providing better service to customer,

and creat more value for customer.

Service 6: Before

placing the order or before shipping, welcome to our factory to take a

visit to inspect our machine. we will pick you up in the airport or

train station and arrange your following schedule in our city to bring

you a nice journey during this visit.

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machiney for more than 10 years, such as plastic

ampoule forming filling and sealing machine, capsule filling machine,

blister packing machine, strip packaging machine, cartoning machine etc.

We have provided services and machines to many different countries and

regions in the whole world, such as Indonesia, Thailand, Malaysia,

Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium,

France, UK, Greece, Italy, Turkey, USA, central and south America such

as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia,

Algeria, Morroco etc. And we always gain the good reputation from

customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factroy, food factroy, supplement factroy, agrochemical factroy such as for pesticide, fertilizer, personal care product factroy, such as for cosmetic product, daily use product, stationery factroy, hardware factroy etc.

If you need more information, please contact us as following:

Ava Duan Email: sales@grand-packing.com Whatsapp/mobile/skype/wechat: +86-13706885851