|

Type

|

LKS-950R

|

LKS-1200R

|

|

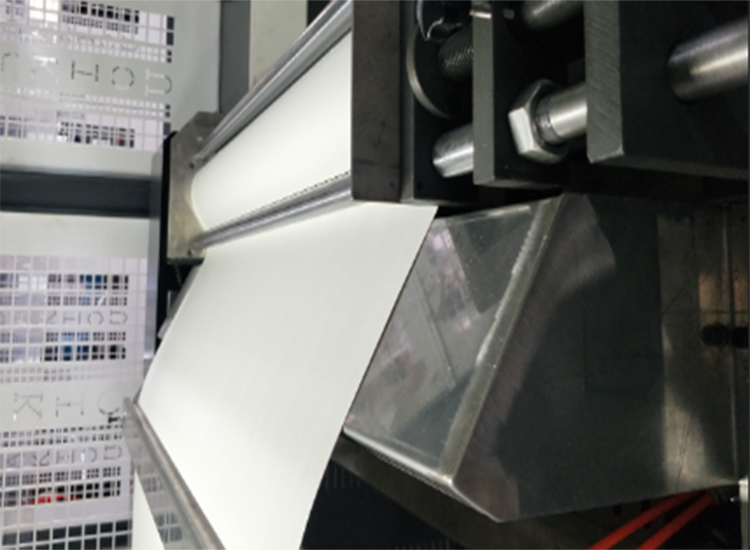

Paper Convey Width:

|

950mm-400mm

|

950mm-400mm

|

|

Max Roll paper diameter:

|

1600mm

|

|

|

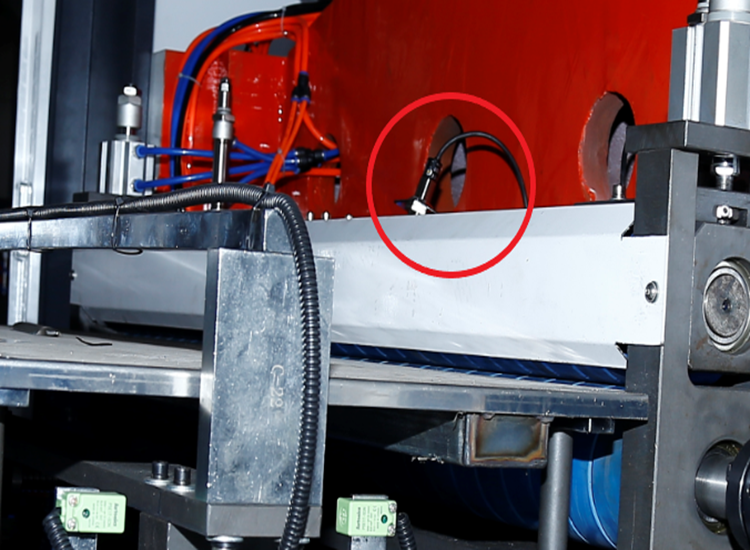

Cut Precision:

|

± 0.10mm

|

|

|

Production capacity

|

150-230times/min

|

|

|

Maximum cutting size:

|

950 x540mm

|

1200 x640mm

|

|

Suitable Material:

|

100-800g/m2 white cardboard, PE coated paper, Kraft paper.etc

As long as your material can be roll , the machine can die cut.

|

|

|

Maximum Pressure:

|

350T

|

|

|

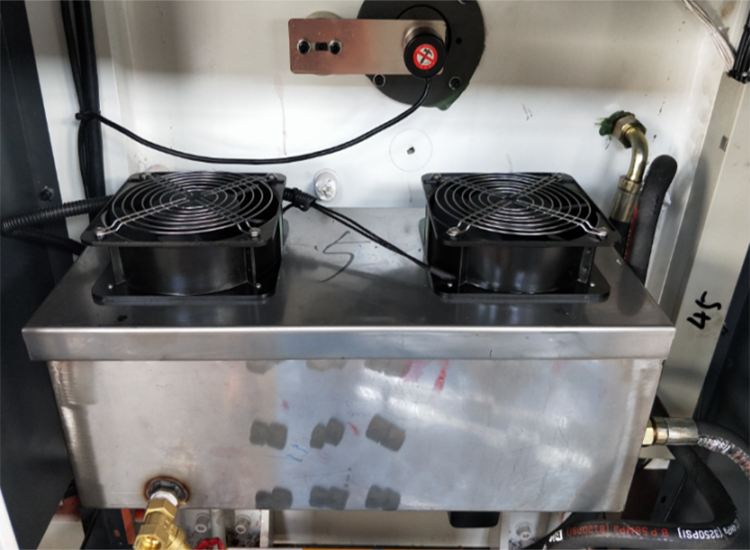

Power:

|

14.5KW

|

|

|

Total Weight:

|

6.3T(standard)

|

8.4 T(standard)

|

|

7.8T(heavy duty)

|

10T (heavy duty)

|

|

|

Overall Dimension:

|

4200 x 2100 x 1850 mm

|

|

|

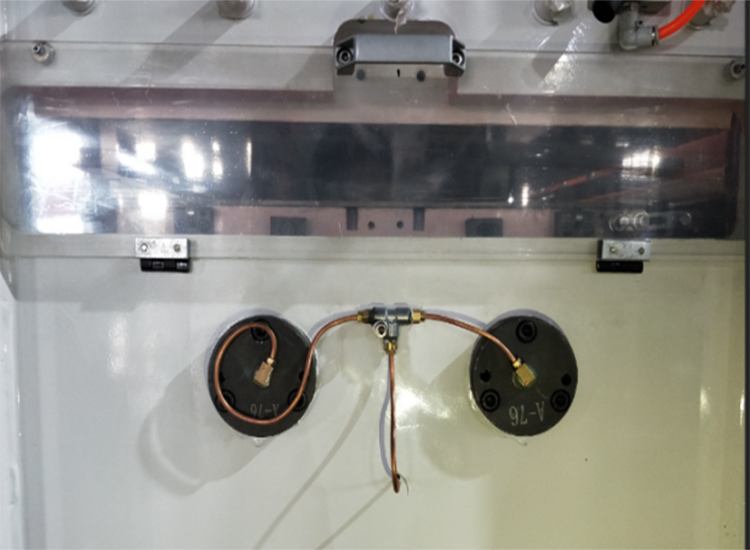

Working Air Source:

|

Air pressure: 0.6Mpa;

|

|

|

Working air: 0.3m³/min;

|

||

|

Other size can be customized.

|

||