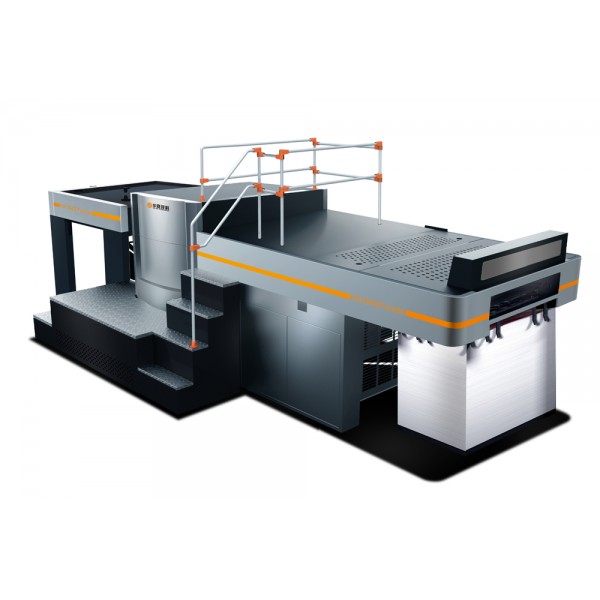

Best solution for thin paper printing inspection; Using feeder and gripper of offset to transfer sheet that is as thin as 40g/㎡ (such as medicines instructions) inspection system check every sheet then bin them separately.

• Max Speed:10000sheets/hour

• Sheet Format:1040×740mm-546×393mm

• Paper Weight:40-350g/㎡

• Max Inspection Speed:130m/min

• Image Resolution:≧ 0.07mm×0.07mm

• Height of Feed Pile:1050mm

• Height of Delivery and Rejection Pile:910mm

• Machine Specifications: Size:6450×2900×2400mm; Power:7.5kw;Weight:6000kg

• Main Equipment:Electrostatic ion blowUltrasonic double sheet testing

• Inspection Station:Frontside inspection station 1:print quality inspection; Frontside inspection station 2: embossing,varnishing,foil stamping; Backside inspection station 1:print quality inspection

• Defect Types:Smear oil dirty white dot black dot dirty spot rust spot scratch missing color difference of both sides.

• Before die cutting make double-side inspection of the sheet products;

• Using offset press's feeder and gripper to transfer the sheets solving thin paper printing quality inspection problems;

• It may has 5 inspection stations at most which make it possible to inspect all kinds of printing quality;

• There is separated acception bin and rejection bin;

• Have an accurate count function;

Beijing SINOMV Technologies (Group) is a high-tech enterprise focused on machine vision and image quality

inspection solution. Located in Beiwu Innovation Park, Zhongguancun in Beijing, SINOMV Technologies (Group)

now has more than 200 stuffs, of which 60 are highly educated talents including PhDs and MSs.

As the pioneer in visual inspection technology industry, SINOMV believes that innovation independently is

the inexhaustible motive force for its development. It possesses various experimental laboratories, including

optical imaging laboratory, electrical control laboratory, software testing laboratory, photoelectric debugging

and hardware laboratory, and established color science and engineering joint laboratory with Chromasens,

Beijing Institute of Technology and Spain Granada University to enhance the ability of R&D.

Through ten years development, SINO-MV has obtained 22 national patents and 17 software copyrights,

included mass data processing in high speed, intelligent modeling, multi-spectra image acquirement, high resolution image acquirement, special material surface image acquirement. The application fields of our

inspection system includes banknote printing industry, security printing industry(check printing, ID and

passport printing), printing industry(package printing, color box printing, label printing, book printing ), and

electronic industry(LED, PCB). Holding modern management concept and brilliant technology achievements,

all of our products are produced according to the standard of CE and ISO9001, and winning many honorary

titles, such as National High-tech Enterprise, Software Enterprise, Zhongguancun Gazelle Enterprise,etc.

SINO-MV persists in taking the market as the engine to drive R&D, guiding production by data, providing

basis for quality improvement and creating a steady flow of values for customers . Since the group was founded,

it has provided more than 400 sets inspection machines and has offices at Shenzhen , Shanghai and Henan

province, all of which forms a comprehensive and effective pre-sale and after-sale service network. With our

reliable products and high quality service,we are highly praised by customers.

Settle down on technologies and pursue our responsibilities, SINOMV will shoulder social responsibility

bravely, be more opening-up to promote the progress of science and technology, taking unremitting effects

to make Chinese prints competitive all over the world.

Wap Version

Wap Version