For printing substrate and installation of equipment is not listening, using different cooling methods can achieve better results. On the offset, gravure, flexo, coating and other high-speed printing presses, we use targeted cooling. In the cooling mode using the auxiliary air-cooled, to achieve the desired cooling effect. In the workshop 25 degrees Celsius, the print drying temperature not higher than 35 degrees Celsius, while the use of such cooling without worrying about the fire that occurred UV printing. Do not worry about drinking printing paper received tooth row, row of teeth between the color groups excessive heat and damage

Structures for different devices required for drying printed, using different ways to achieve the desired reflection drying effect, UV offset printing machine in the Division I gather reflection mode, so lower power required curing, thereby saving play.

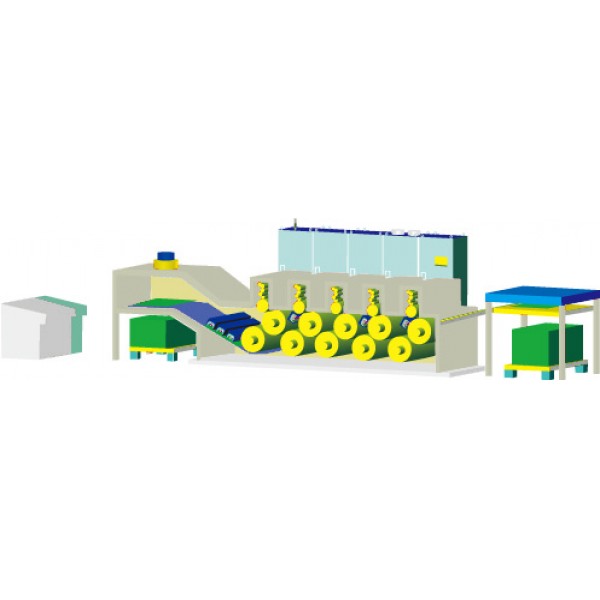

We have a high-quality research and development team dedicating to design, produce, transform and technically support printing drying solutions. Large elite team with professional engineers carefully research, design and develop printing drying equipment systems with high safety factor, high technology, high stability, high efficiency and simple operation.

Every set of printing drying equipment produced by JingKe has gone through rigorous testing and burn-in test, with the purpose of providing you with qualified printing drying equipment. Over the years we have been focusing on the study of the drying technology in the printing industry. After years of development and accumulation, we have been widely recognized by domestic and foreign customers in the printing area.

About Us | Help | Our Services | Security and Privacy | Terms of Use | Declaration | Contact Us

Wap Version

Wap Version